Pegaint Magnets is a global magnet supplier and manufacturer. We have focused on rare earth permanent magnets and magnetic products since our establishment in the 2004s. Our product range includes rare earth materials, Neodymium Magnets, Samarium Cobalt Magnets, AlNiCo Magnets, Ferrites/Ceramic Magnets, Magnetic Assemblies, and Bonded Magnets. We provide our customers in multiple fields, including Wind Turbines, MRI, Loudspeakers, NMR (Nuclear Magnetic Resonance), and Medical & Mechanical Devices, with a large quantity of rare earth permanent magnetic products and materials at competitive prices.

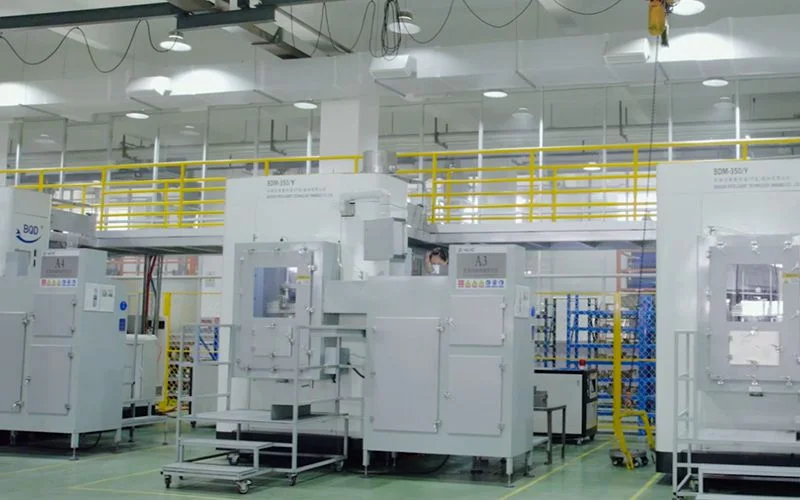

Professional Magnet Factory:

Our manufacturing facility is fully dedicated to producing high-quality magnets specifically designed for professional applications. We use only the finest materials and employ state-of-the-art production techniques to ensure that our products meet the highest industry standards. As a leading worldwide magnet supplier, we are committed to providing our customers with reliable and long-lasting magnets, including Neodymium (NdFeB), Samarium Cobalt (SmCo), Alnico, or Ferrite magnets, magnetic assemblies, and rare earth materials.

If you need high-quality, custom magnets, look no further. Reach out to us, and let’s bring your magnetic ideas to life!

Capabilities:

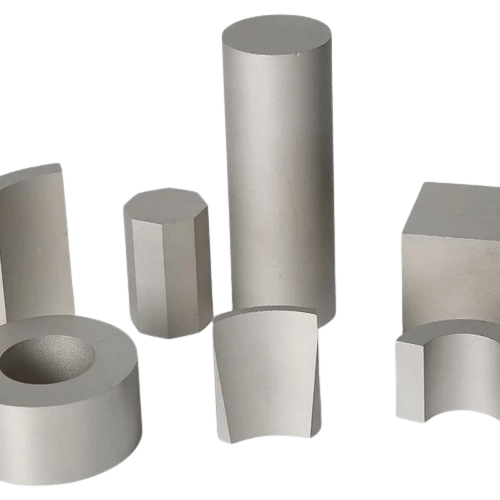

Pegaint Magnets has advanced processing equipment and technology that allows us to produce 4,500 tons of magnets every year. We have devoted over two decades to researching and developing a unique production process that ensures the creation of top-quality magnet products. Our company has more than 700 processing and precision machining equipment that can handle a variety of complex shapes and high-precision magnet products.

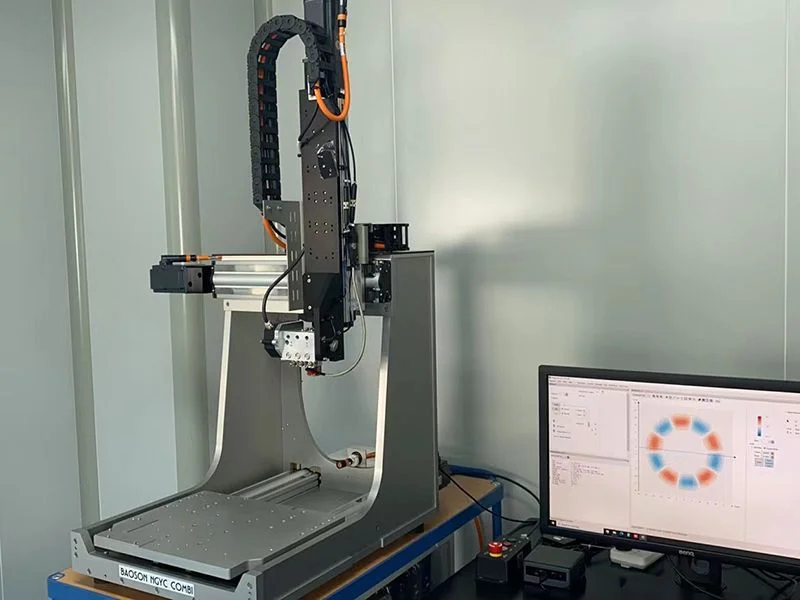

QUALITY INSPECTION CENTER

Magnet Manufacturing Process

1. Ingredient Mixing

Precise proportioning according to grade specifications

2. Melting

Key controls include vacuum pressure, voltage, argon filling capacity, refining time, and cooling temperature and time

3. Powder Production

Coarse, medium, and fine crushing with control over rotational speed, nitrogen pressure, oxygen content, and particle size

4. Compression Molding

Main controls include mold dimensions, powder weight, temperature, humidity, pressure, and time

5. Sintering and Aging

Key control points are vacuum pressure, argon pressure, sintering and aging temperatures, and duration

6. Blank Inspection

Inspection of external dimensions and observation of Max demagnetization curves

7. Machining

Main controls include dimensional tolerances, positional tolerances, coatings, and appearance

8. In-process Inspection

Inspection of appearance, dimensions, positional tolerances, and quantity

9. Final Inspection

Comprehensive inspection of appearance, dimensions (full or sampling), positional tolerances (full or sampling), and magnetic performance (full or sampling) as per requirements

10. Packaging and Delivery

Custom or standard packaging, quantity verification, boxing, magnetizing shields, and testing reports

Recognized for Excellence

Thanks to our scientific management practices and strict adherence to product quality, Pegaint magnets has been recognized as an Enterprise for Export Product Quality Assurance and a Prestigious Brand.

Automated testing equipment for magnetic moment and inclination

Magnetic inclination angle detectors

Particle analyzers from Germany

Imaging measurement devices

Automated testing equipment for magnetic moment and inclination

Magnetic inclination angle detectors

Particle analyzers from Germany

Imaging measurement devices

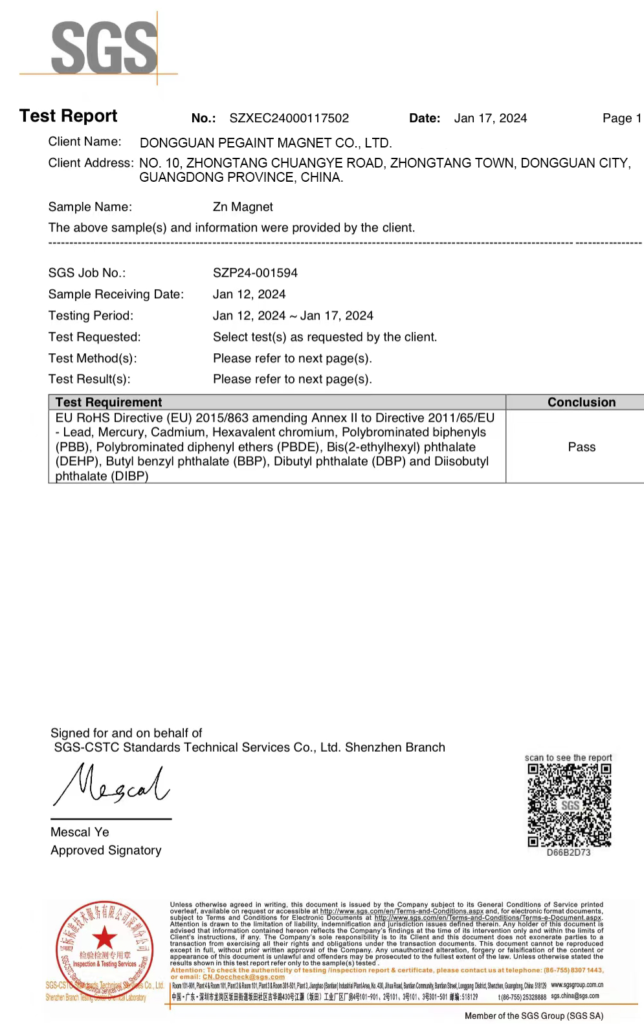

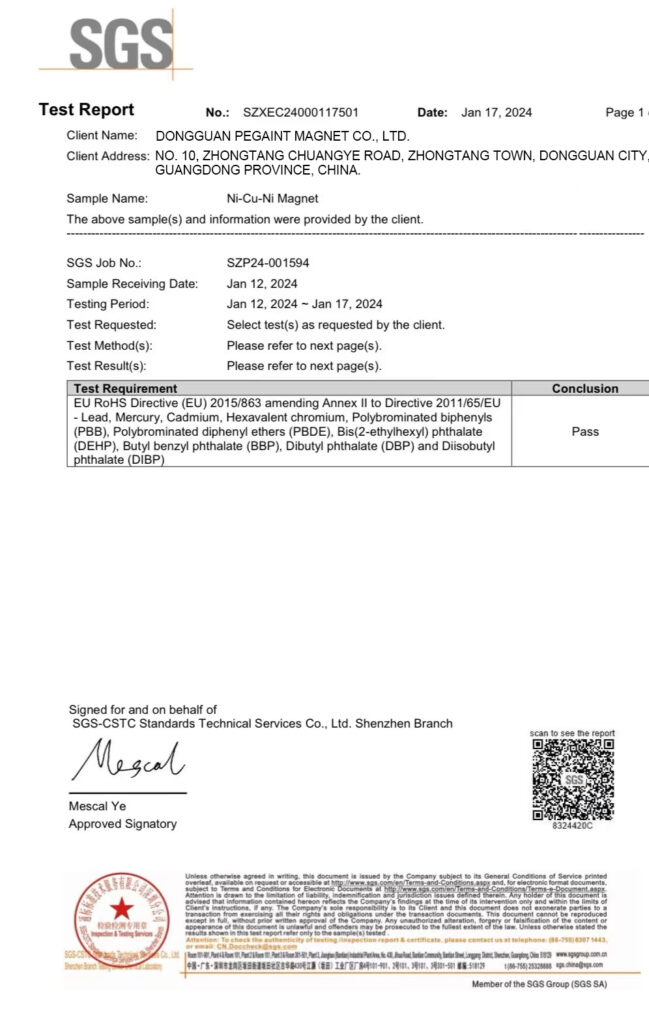

OUR CERTIFICATES

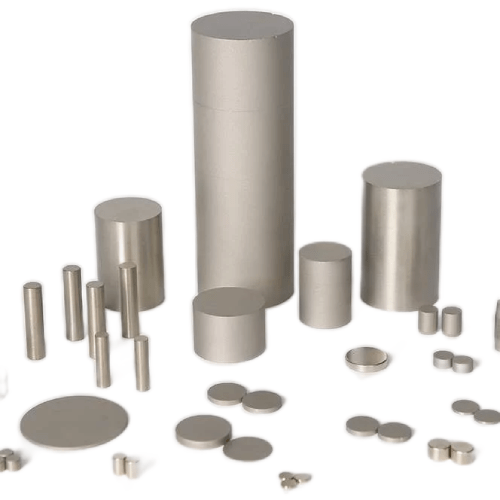

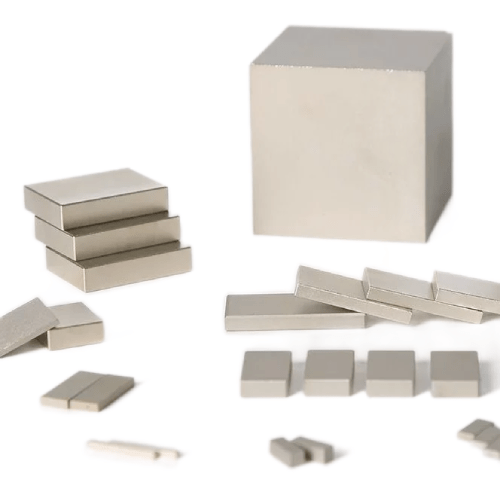

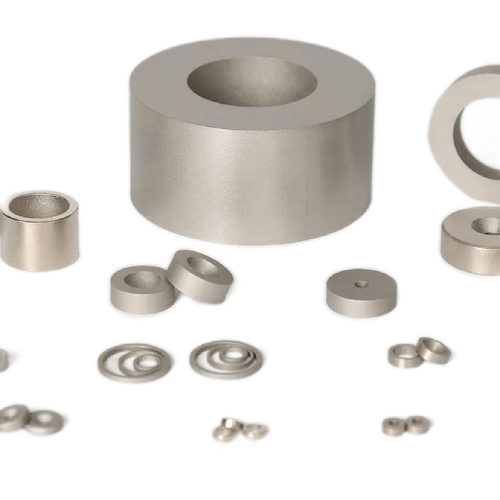

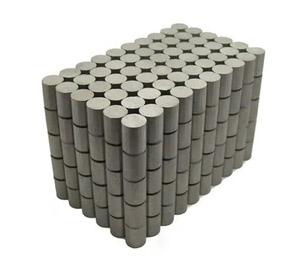

Custom Samarium Cobalt Magnet

Samarium Cobalt magnets (SmCo)are a type of rare earth magnet known for their strong magnetic properties and resistance to high temperatures. These magnets comprise samarium (Sm), cobalt (Co), and other rare earth elements.

Pegaint Magnets can manufacture Samarium Cobalt magnets (SmCo) which operation temperature can be 600°C.

Samarium Cobalt magnets provided by Pegaint Magnets are highly resistant to corrosion and oxidation, with high energy products and an extremely low temperature coefficient. The maximum operating temperature can reach 250°C to 600°C depending on the grades, with no limit on negative temperatures. At working temperatures above 180°C, SmCo magnets’ temperature and chemical stability exceed those of NdFeB magnets.

With over ten years of industry experience, Pegaint Magnets can supply a wide range of customized Samarium Cobalt (SmCo) Magnets according to requests.

What is the difference between samarium cobalt magnets and neodymium iron boron magnets?

1:Temperature Resistance

Samarium cobalt magnets can be used at a higher temperature than NdFeB magnets, up to 300 degrees Celsius or more.

2:Higher Performance

Above180degrees Celsius, samarium cobalt magnets start to provide higher performance than NdFeB magnets.

3:Corrosion Resistance

Samarium Cobalt Magnets has good corrosion resistance and generally does not require surface treatment, while NdFeB is easy to be corroded.

4:Price Comparisons

The general price of samarium cobalt magnets is higher than NdFeB magnets.

Comparisons

Among all magnets, samarium cobalt magnets are the most brittle one.

What are the Common Applications of SmCo Magnets

Samarium cobalt magnets are widely used in the military, wind energy, semiconductor, petroleum, manufacturing, aerospace, medical, automotive, electric power, and energy industries, such as high-performance motors, generators, turbo machinery, electric motors, magnetic separation devices, sensor systems, wind turbine equipment, medical devices, magnetic drive components and more.