- Zhongtang Town, Dongguan City, Guangdong ,China

- [email protected]

- +8619065048753

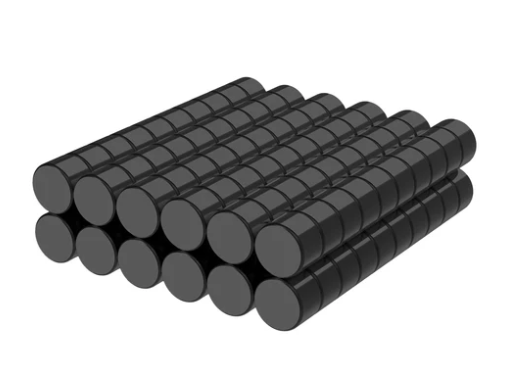

Disc Epoxy Coated Magnet

- Home

- PRODUCTS

- Neodymium Magnets

- Disc Epoxy Coated Magnet

Disc Epoxy Coated Magnets are typically rare-earth magnets, often made from neodymium, which are coated with an epoxy resin to provide protection against corrosion and physical damage. Here are some common technical parameters you might find for these magnets:

- 1. Material: Neodymium-Iron-Boron (NdFeB)

- 2. Coating: Epoxy

- 3. Shape: Disc

- 4. Dimensions: Diameter and thickness (e.g., 10 mm diameter x 2 mm thickness)

- 5. Magnet Grade: Ranges from N35 to N52 (indicating the strength of the magnet, with N52 being the strongest commonly available grade)

- 6. Magnetic Properties: – Remanence (Br): Indicates the residual magnetic field. Typically ranges from 1.1 to 1.5 Tesla. – **Coercivity (Hcb)**: The resistance to demagnetization. Typically ranges from 836 to 923 kA/m. – Intrinsic Coercivity (Hcj): The resistance to demagnetization under the influence of an opposing magnetic field. Typically ranges from 955 to 2000 kA/m. – Maximum Energy Product (BHmax): The density of magnetic energy. Typically ranges from 280 to 422 kJ/m³.

- 7. Operating Temperature: Maximum operating temperatures can range from 80°C to 200°C depending on the grade and specific composition of the magnet.

- 8. Density: Approximately 7.5 g/cm³

- 9. Magnetic Pole Orientation: Axially magnetized (North and South poles are on the flat faces of the disc)

- 10. Epoxy Coating Thickness: Typically around 10-20 micrometers.

Disc Epoxy Coated Magnets are widely used in various applications across different industries due to their strong magnetic properties and corrosion resistance. Here are some common application areas:

- 1. Electronics: – Used in sensors, microphones, and speakers. – Employed in computer hard drives and other data storage devices. – Applied in mobile phones and other handheld devices for magnetic attachments.

- 2. Automotive Industry: – Utilized in electric motors and generators. – Used in magnetic sensors and actuators. – Employed in various components of electric and hybrid vehicles.

- 3. Medical Devices: – Used in MRI machines and other medical imaging equipment. – Applied in magnetic therapy devices and health monitoring sensors.

- 4. Renewable Energy: – Utilized in wind turbine generators. – Employed in various types of energy harvesting devices.

- 5. Industrial Applications: – Used in magnetic separators and magnetic filters. – Applied in holding and lifting equipment. – Employed in magnetic couplings and clutches.

- 6. Consumer Products: – Used in magnetic closures for bags, boxes, and cases. – Employed in toys and educational tools. – Applied in DIY projects and crafts for magnetic attachments.

- 7. Security and Defense: – Utilized in magnetic locks and security systems. – Employed in various types of sensors and detection devices.

- 8. Aerospace: – Used in navigation systems and instrumentation. – Employed in various components of aircraft and spacecraft.

Disc Epoxy Coated Magnet provides an additional layer of protection, making these magnets suitable for environments where they might be exposed to moisture, chemicals, or physical wear.

We supply approved neodymium rare earth magnets in a variety of shapes, sizes, premium grades (from N30 to N52) and surface treatments. Our extensive inventory of NdFeB magnets includes discs, blocks, strips, rings, rods and more. Not all of our magnets are displayed on this website. If you can’t find the magnet you need, contact us today and our staff will make sure you find the best magnet for your application.

Subscribe Now

Don’t miss our future updates! Get Subscribed Today!

©2024. Dongguan Pegaint magnet CO.,LTD All Rights Reserved.