- Zhongtang Town, Dongguan City, Guangdong ,China

- [email protected]

- +8619065048753

How to produce magnet

Producing a magnet involves aligning the magnetic domains of a material. Here’s a simple overview of the process:

Materials Needed

– Ferromagnetic material (e.g., iron, nickel, cobalt)

– Magnetizing equipment (e.g., strong magnet, electric coil)

– Power source (if using electric coil)

Methods

1. Using a Strong Magnet:

– Materials: Ferromagnetic object, strong magnet.

– Process:

1. Stroke Method: Stroke the ferromagnetic material with one pole of a strong magnet, always in the same direction. Repeat several times.

2. Contact Method: Place the ferromagnetic material in contact with a strong magnet for an extended period.

2. Using an Electric Coil (Electromagnetism):

– Materials: Ferromagnetic rod, insulated copper wire, power source (battery or DC power supply).

– Process:

1. Wrap the Coil: Tightly wrap the insulated copper wire around the ferromagnetic rod, leaving enough wire at both ends to connect to a power source.

2. Connect to Power Source:Connect the ends of the wire to the power source, allowing current to flow through the coil. This creates a magnetic field, magnetizing the rod.

3. Duration: Leave the current flowing for a few minutes to ensure the rod is adequately magnetized.

Steps for Each Method:

Stroke Method:

1. Prepare the Materials: Get a strong magnet and the ferromagnetic object you wish to magnetize.

2. Stroke in One Direction: Consistently stroke the magnet along the object in one direction. This aligns the magnetic domains in the material.

3. Repeat: Repeat the stroking process multiple times to strengthen the magnetization.

Electromagnetism Method:

1. Wrap the Wire: Wrap the insulated wire around the ferromagnetic rod, creating a tight coil.

2. Connect to Power Source:Attach the ends of the wire to a power source. When the current flows, it generates a magnetic field.

3. Allow Time: Leave the current flowing for several minutes.

4. Disconnect and Test: Disconnect the power source and test the rod for magnetism by checking if it attracts small metal objects.

Safety Tips:

– When using electricity, ensure proper insulation to avoid electric shocks.

– Handle strong magnets with care to avoid injury.

By following these methods, you can produce a magnet from a ferromagnetic material.

Producing neodymium-iron-boron (NdFeB) magnets involves several detailed steps, from preparing the raw materials to the final magnetization process. Here’s an overview of the main stages involved:

1. Raw Material Preparation

– Composition: The primary elements needed are neodymium (Nd), iron (Fe), and boron (B), along with small amounts of other elements like dysprosium (Dy) or praseodymium (Pr) for specific properties.

– Melting: The raw materials are melted together in a vacuum induction furnace to form an alloy. This helps to ensure that the materials are thoroughly mixed and any impurities are removed.

2. Casting and Crushing

– Casting: The molten alloy is cast into molds to form ingots.

– Crushing: These ingots are then crushed into coarse powder.

3. Milling

– Jet Milling: The coarse powder is further refined using a jet mill to create fine particles with a size in the range of micrometers. This is crucial for the uniformity and quality of the final magnets.

4. Pressing and Aligning

– Pressing:The fine powder is then pressed into a desired shape, typically in the presence of a magnetic field. This field helps align the magnetic domains in the same direction, which is critical for the magnet’s final magnetic properties.

5. Sintering

– Sintering:The pressed shapes are sintered in a vacuum furnace at high temperatures (about 1,000-1,200°C). This process fuses the particles together without melting them, resulting in a solid, dense magnet.

6. Heat Treatment

– Heat Treatment: The sintered magnets undergo additional heat treatments to optimize their magnetic properties and structural stability.

7. Machining

– Machining: The sintered and treated magnets are machined to precise dimensions. This can involve grinding, cutting, and drilling, depending on the application.

8. Coating

– Coating:NdFeB magnets are prone to oxidation, so they are often

“How to produce a magnet” is crucial for several reasons:

Technological Innovation

Understanding the production process of magnets, especially high-performance types like neodymium-iron-boron (NdFeB) magnets, is essential for technological advancement. Knowledge of this process allows for the development of more efficient, powerful, and miniaturized magnetic devices, which are fundamental in electronics, renewable energy, automotive, and medical industries.

- Quality Control

A detailed description of the magnet production process ensures that high-quality standards are maintained. Each step, from raw material selection to final magnetic testing, is critical for producing magnets with consistent and reliable performance. This is especially important for applications requiring high precision and durability.

- Cost Efficiency

Knowing the production process helps in identifying areas where costs can be reduced without compromising quality. Innovations in production techniques, such as improved alloy formulations or more efficient sintering methods, can significantly lower manufacturing costs and increase competitiveness.

- Environmental Impact

The production of magnets involves the use of rare earth elements, which have environmental and geopolitical implications. Describing the process in detail highlights the importance of sustainable practices, such as recycling and minimizing waste, and can drive efforts towards more eco-friendly production methods.

- Educational Value

A comprehensive explanation of magnet production serves as an educational tool for students, engineers, and scientists. It helps them understand the complexities and challenges involved, fostering a deeper appreciation of material science and engineering principles.

- Industry Standards

Detailed process descriptions contribute to the establishment and adherence to industry standards. This ensures interoperability and compatibility of magnetic products across different manufacturers and applications, promoting consistency and reliability in the market.

- Innovation and Research

Documenting the production process can stimulate further research and innovation. Scientists and engineers can build on existing knowledge to explore new materials, techniques, and applications, driving the field forward.

- Supply Chain Transparency

A clear understanding of how magnets are produced enhances supply chain transparency. It allows stakeholders to better assess risks, manage resources, and plan for contingencies, ensuring a stable supply of critical components.

- In summary, describing the production process of magnets is vital for advancing technology, ensuring quality, reducing costs, promoting sustainability, educating future engineers, maintaining industry standards, fostering innovation, and enhancing supply chain transparency.

Producing magnets, particularly advanced ones like neodymium-iron-boron (NdFeB) magnets, involves several cutting-edge technologies that enhance their performance, reduce costs, and minimize environmental impact. Here are some of the latest techniques used in How to produce magnet:

- Powder Injection Molding (PIM)

Powder injection molding combines the benefits of powder metallurgy and plastic injection molding. This technology allows for the production of complex-shaped, small magnets with high precision and minimal waste. It is especially useful for NdFeB magnets.

- Hot Isostatic Pressing (HIP)

Hot isostatic pressing uses a combination of high temperature and high pressure to densify sintered magnet blanks. This technology can eliminate internal defects, improving the mechanical strength and magnetic properties of the magnets.

- Additive Manufacturing (3D Printing)

Additive manufacturing, particularly 3D printing, is gradually being applied to magnet production. This technology enables the creation of custom-designed magnets with complex geometries and internal structures tailored to specific requirements.

- High-Throughput Production Technologies

High-throughput production involves automation and rapid production lines to increase efficiency and output. This includes automated pressing, sintering, and machining steps, reducing human intervention and production cycles.

- Efficient Recycling Technologies

For NdFeB magnets, advanced recycling technologies are being developed to extract and reuse rare earth elements. These technologies help reduce reliance on new mineral resources and minimize environmental impact.

- Precision Alloy Composition Control

Advanced metallurgical techniques allow for precise control of the alloy composition and microstructure of the magnets, optimizing their magnetic performance and thermal stability. This includes the use of sophisticated melting and alloying equipment.

- Magnetic Nanomaterials

The application of nanotechnology enables the development of magnetic nanomaterials with unique properties. These materials hold significant potential for high-tech applications such as biomedical imaging and high-frequency electronic devices.

- Environmentally Friendly Production Processes

To reduce environmental impact, new production technologies include the use of eco-friendly materials, reduced use of harmful chemicals, and improved waste management practices. For example, water-based or low-toxicity binders are used instead of traditional organic solvents.

- Magnetic Orientation Control Technology

During production, external magnetic fields are used to control the orientation of magnetic particles to maximize the magnetic performance of the final product. This technique is widely used in powder metallurgy and pressing processes.

- Advanced Sintering Techniques

New sintering techniques, such as spark plasma sintering (SPS), involve rapid heating and cooling processes, significantly shortening sintering times and improving the density and uniformity of the magnets.

- Conclusion

By adopting these cutting-edge technologies, magnet production becomes more efficient and economical, resulting in magnets with superior performance and the ability to meet diverse and complex requirements. These advancements drive the applications and development of magnets across various industries.

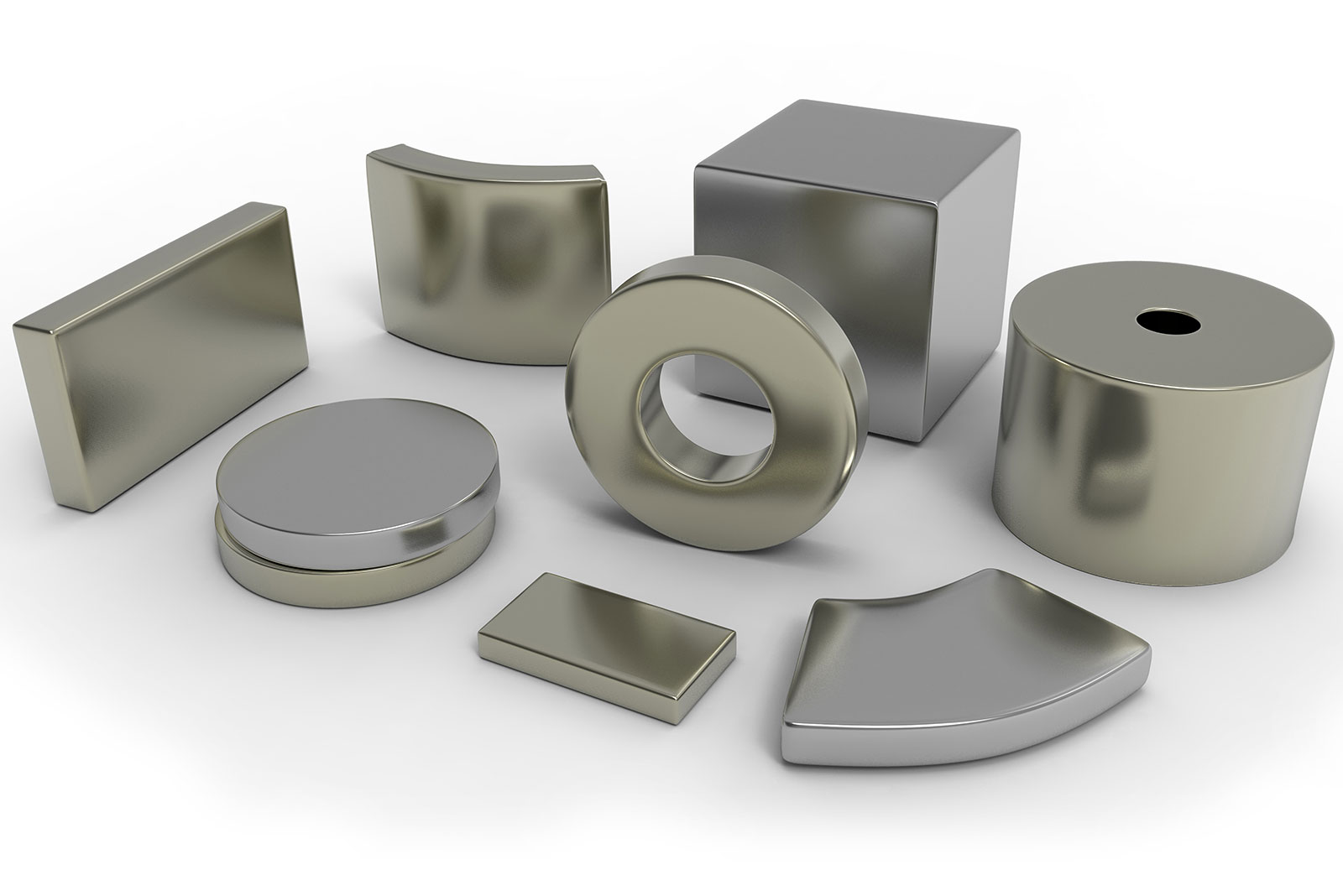

We supply approved neodymium rare earth magnets in a variety of shapes, sizes, premium grades (from N30 to N52) and surface treatments. Our extensive inventory of NdFeB magnets includes discs, blocks, strips, rings, rods and more. Not all of our magnets are displayed on this website. If you can’t find the magnet you need, contact us today and our staff will make sure you find the best magnet for your application.

Subscribe Now

Don’t miss our future updates! Get Subscribed Today!

©2024. Dongguan Pegaint magnet CO.,LTD All Rights Reserved.