- Zhongtang Town, Dongguan City, Guangdong ,China

- [email protected]

- +8619065048753

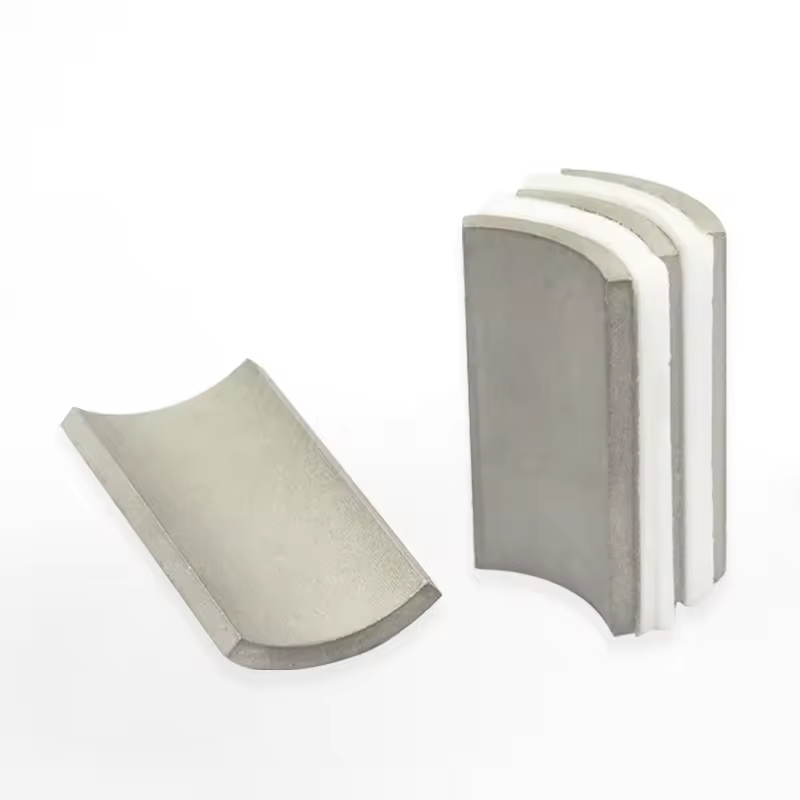

Samarium Cobalt Arc Magnet

- Home

- PRODUCTS

- Samarium Cobalt Magnets

- Samarium Cobalt Arc Magnet

Samarium Cobalt Arc Magnet is an ideal solution to high-temperature applications and offer

Samarium Cobalt Arc Magnet has good corrosion resistance. Sm1Co5 does not rust because it does not contain iron.

However, Sm2Co17 should be coated with a protective coating in very wet conditions to minimize the risk of surface corrosion. However, Sm1Co5 does not rust because it does not contain iron.

Samarium Cobalt Arc Magnets are expensive and subject to price fluctuations (cobalt is market price sensitive)

Samarium Cobalt Arc Magnets exhibit magnetic anisotropy, meaning they can only be magnetized in the axis of their magnetic orientation. This is done by aligning the crystal structure of the material during the manufacturing process.

Samarium Cobalt Arc Magnets known for their high magnetic strength, excellent temperature stability, and resistance to demagnetization. Here are the typical technical parameters for powerful SmCo arc magnets:

1. Material Composition: – Samarium (Sm): 35% – Cobalt (Co): 60% – Other elements such as Iron (Fe), Copper (Cu), Zirconium (Zr), and Hafnium (Hf) may be included to enhance specific properties. 2. Magnetic Properties: – Residual Induction (Br): 9,500 – 11,000 Gauss (0.95 – 1.1 Tesla) – Coercive Force (Hc): 9,000 – 10,500 Oersteds (716 – 835 kA/m) – Intrinsic Coercive Force (Hci): 15,000 – 30,000 Oersteds (1,194 – 2,388 kA/m) – Energy Product (BHmax): 22 – 30 MGOe (175 – 239 kJ/m³) 3. Physical Properties: – Density: 8.2 – 8.4 g/cm³ – Electrical Resistivity: 0.8 – 0.9 μΩ·m – Thermal Conductivity: 10 – 15 W/(m·K) 4. Temperature Stability: – **Maximum Operating Temperature**: 250 – 350°C (482 – 662°F), depending on the specific grade – **Curie Temperature**: 700 – 850°C (1,292 – 1,562°F) – SmCo magnets maintain high magnetic stability over a wide temperature range and are less prone to thermal demagnetization compared to other types of permanent magnets. 5. Mechanical Properties: – Hardness: Vickers 500 – 600 HV – Compressive Strength: 800 – 1,000 MPa – Tensile Strength: Low, brittle material; care must be taken to avoid mechanical stress 6. Corrosion Resistance: – SmCo magnets have excellent corrosion resistance and typically do not require coating or plating for protection in most environments. 7. Tolerance: – Typical machining tolerance for SmCo magnets is ±0.05mm, though this can vary based on specific manufacturing capabilities and requirements.

Samarium Cobalt Arc Magnet is specialized forms of SmCo magnets designed for specific applications that require their unique shape and properties. Key applications include:

- 1.Electric Motors:Powerful Samarium Cobalt Arc Magnets are widely used in brushless DC motors and other types of electric motors. Their shape allows for efficient magnetic field distribution, improving motor performance and efficiency.

- 2. Generators: In generators, arc SmCo magnets help convert mechanical energy into electrical energy efficiently, especially in high-performance and high-temperature environments.

- 3. Magnetic Couplings: These magnets are used in magnetic couplings, providing a non-contact method of torque transmission that can operate in harsh or corrosive environments.

- 4. Magnetic Bearings: Arc SmCo magnets are utilized in magnetic bearing systems, where they provide stable and frictionless support for rotating parts, enhancing the longevity and reliability of machinery.

- 5. Sensors and Actuators: The precise magnetic field control provided by arc-shaped SmCo magnets makes them ideal for use in various sensors and actuators, contributing to high accuracy and performance.

- 6. Aerospace Applications: Their ability to maintain magnetic properties at high temperatures and in extreme conditions makes arc SmCo magnets suitable for aerospace applications, including control systems and advanced propulsion technologies. These applications benefit from the arc SmCo magnet’s shape, which optimizes magnetic field distribution and provides robust performance under demanding conditions.

We supply approved neodymium rare earth magnets in a variety of shapes, sizes, premium grades (from N30 to N52) and surface treatments. Our extensive inventory of NdFeB magnets includes discs, blocks, strips, rings, rods and more. Not all of our magnets are displayed on this website. If you can’t find the magnet you need, contact us today and our staff will make sure you find the best magnet for your application.

Subscribe Now

Don’t miss our future updates! Get Subscribed Today!

©2024. Dongguan Pegaint magnet CO.,LTD All Rights Reserved.