- เมืองจงทัง เมืองตงกวน กวางตุ้ง จีน

- [email protected]

- +8619065048753

Title: Enhancing Efficiency and Sustainability with Magnet Motors: A Key Solution for Modern Industry

In nowadays’s industry, optimizing energy efficiency and reducing operational costs are paramount. Magnet motors, known for their high efficiency and reliability, have emerged as a vital technology to address these goals. By minimizing energy waste and ensuring a sustainable operational life, magnet motors have significant applications across manufacturing, electric vehicles, HVAC systems, and other industries. This article explores the key benefits, applications, and future potential of magnet motors as an innovative solution for sustainable industrial operations.

What is Magnet Motor?

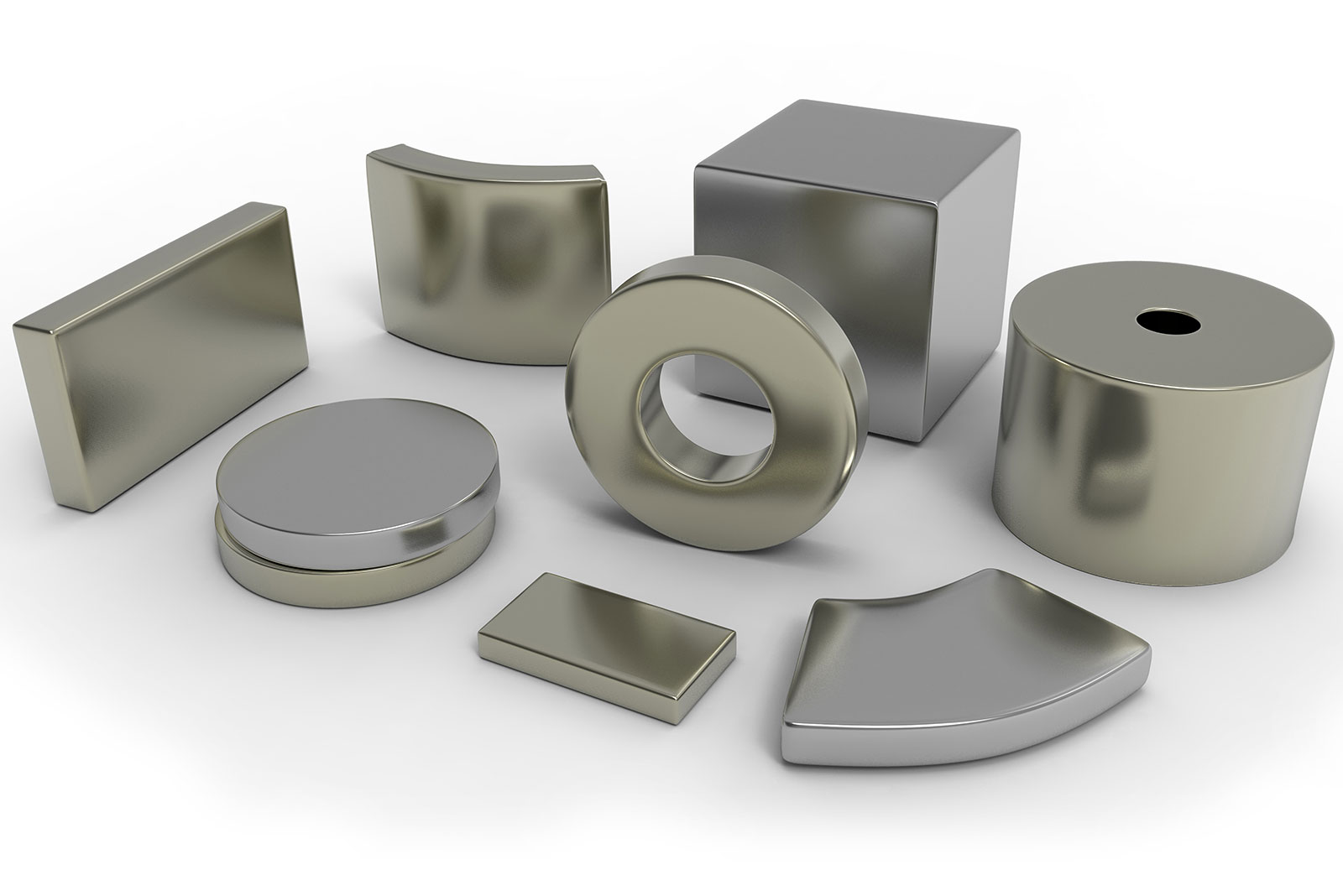

Magnet motor, often permanent magnet (PM) motor, use permanent magnet made of rare-earth materials like neodymium or samarium-cobalt to produce a strong, constant magnetic field. Unlike traditional motors that rely on electric coils to generate a magnetic field, magnet motors are more efficient, compact, and durable. These motors are especially known for high torque density and minimal heat production, making them ideal for both high-speed and precision applications.

Key Benefits of Magnet Motors

Magnet motors bring several key advantages that make them well-suited for modern industry, including:

1. Enhanced Energy Efficiency: With lower energy losses than conventional motors, magnet motors offer better energy utilization, which reduces both operational costs and environmental impact. This efficiency becomes crucial for energy-intensive industries and contributes significantly to overall sustainability.

2. High Power Density and Torque: Magnet motors provide superior torque, even at low speeds, which makes them highly versatile. This is particularly beneficial for applications in transportation and robotics, where powerful and precise control is essential.

3. Compact Size and Lightweight: Due to their compact design, magnet motors are ideal for applications where space and weight are limited, such as in electric vehicles (EVs) and drones. This attribute not only saves space but also enhances mobility and reduces installation challenges.

4. Reliability and Low Maintenance: Magnet motors typically require less maintenance than traditional motors since they lack components like brushes, which wear down over time. This means lower downtime and maintenance costs, which translates into improved productivity.

Applications of Magnet Motors in Industry

The versatility of magnet motors makes them suitable for a broad range of industrial applications, including:

• Electric Vehicles (EVs): Magnet motors are widely used in EVs because of their high efficiency, compact design, and ability to deliver consistent performance over a wide range of speeds. They contribute to longer driving ranges and reduced battery consumption, making EVs more viable and sustainable.

• HVAC Systems: In heating, ventilation, and air conditioning systems, magnet motors help achieve energy efficiency and reduce power consumption. This results in lower electricity costs and contributes to greener building solutions.

• Robotics and Automation: The high torque and precision control offered by magnet motors make them ideal for robotics and automation applications. Their low heat generation is particularly advantageous in closed or controlled environments, where maintaining a stable temperature is crucial.

• Renewable Energy: Magnet motors are increasingly used in wind turbines and hydroelectric generators, where efficient and reliable performance is essential. They help to maximize energy conversion rates and reduce mechanical losses, improving overall energy output.

Future of Magnet Motor in Industrial Operations

With advances in materials science and technology, magnet motors are poised to become even more efficient, durable, and versatile. Research is underway to develop stronger and more environmentally friendly magnets that do not rely on rare-earth materials. Additionally, innovations in motor design, such as axial flux motors, promise further improvements in power density and compactness, making magnet motors even more suitable for high-performance and limited-space applications.

As industries seek to transition toward greener, more efficient technologies, magnet motors will play an increasingly important role. With their ability to reduce energy consumption, improve reliability, and lower operational costs, they are a crucial component of the next-generation industrial ecosystem.

Conclusion: The Path to Efficiency and Sustainability

Magnet motors are transforming how industries approach energy efficiency and operational sustainability. Their unique combination of high efficiency, reliability, and versatility make them an ideal choice for industries looking to optimize performance while reducing their environmental footprint. By integrating magnet motors, businesses can enhance productivity, reduce costs, and take a step forward in their sustainability journey.

As the demand for eco-friendly and energy-efficient solutions continues to grow, magnet motors will remain a key asset for businesses worldwide, supporting a sustainable and resilient industrial future.

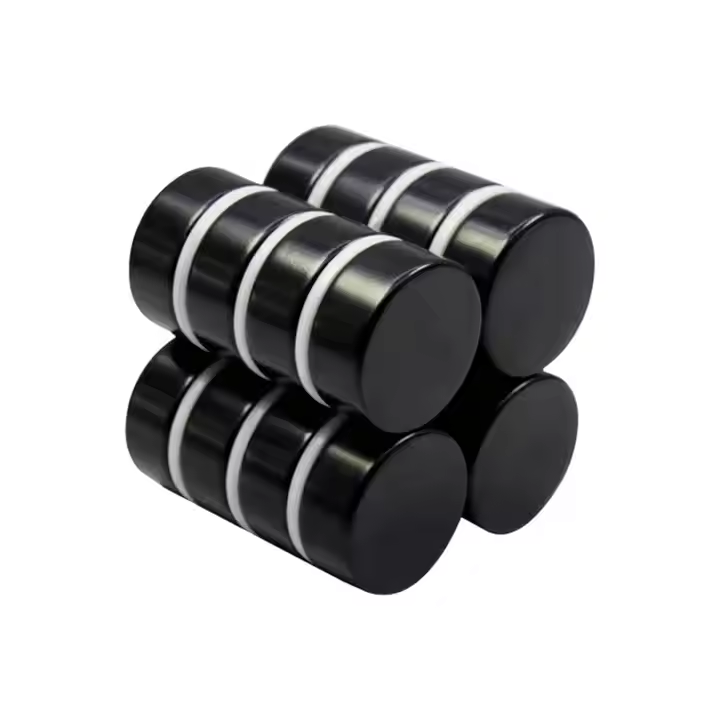

เราจัดหาแม่เหล็กนีโอไดเมียมหายากที่ได้รับการรับรองในรูปทรง ขนาด เกรดพรีเมียม (ตั้งแต่ N30 ถึง N52) และการปรับสภาพพื้นผิวที่หลากหลาย สินค้าคงคลังแม่เหล็ก NdFeB ที่กว้างขวางของเราประกอบด้วยแผ่นดิสก์ บล็อก แถบ แหวน แท่ง และอื่นๆ แม่เหล็กของเราไม่ได้แสดงบนเว็บไซต์นี้ทั้งหมด หากคุณไม่พบแม่เหล็กที่ต้องการ โปรดติดต่อเราวันนี้ เจ้าหน้าที่ของเราจะค้นหาแม่เหล็กที่ดีที่สุดสำหรับการใช้งานของคุณ

สมัครสมาชิกตอนนี้

อย่าพลาดการอัปเดตในอนาคตของเรา! สมัครสมาชิกวันนี้!

©2024. ตงกวน Pegaint แม่เหล็ก CO.,LTD สงวนลิขสิทธิ์