- Stadt Zhongtang, Stadt Dongguan, Guangdong, China

- [email protected]

- +8619065048753

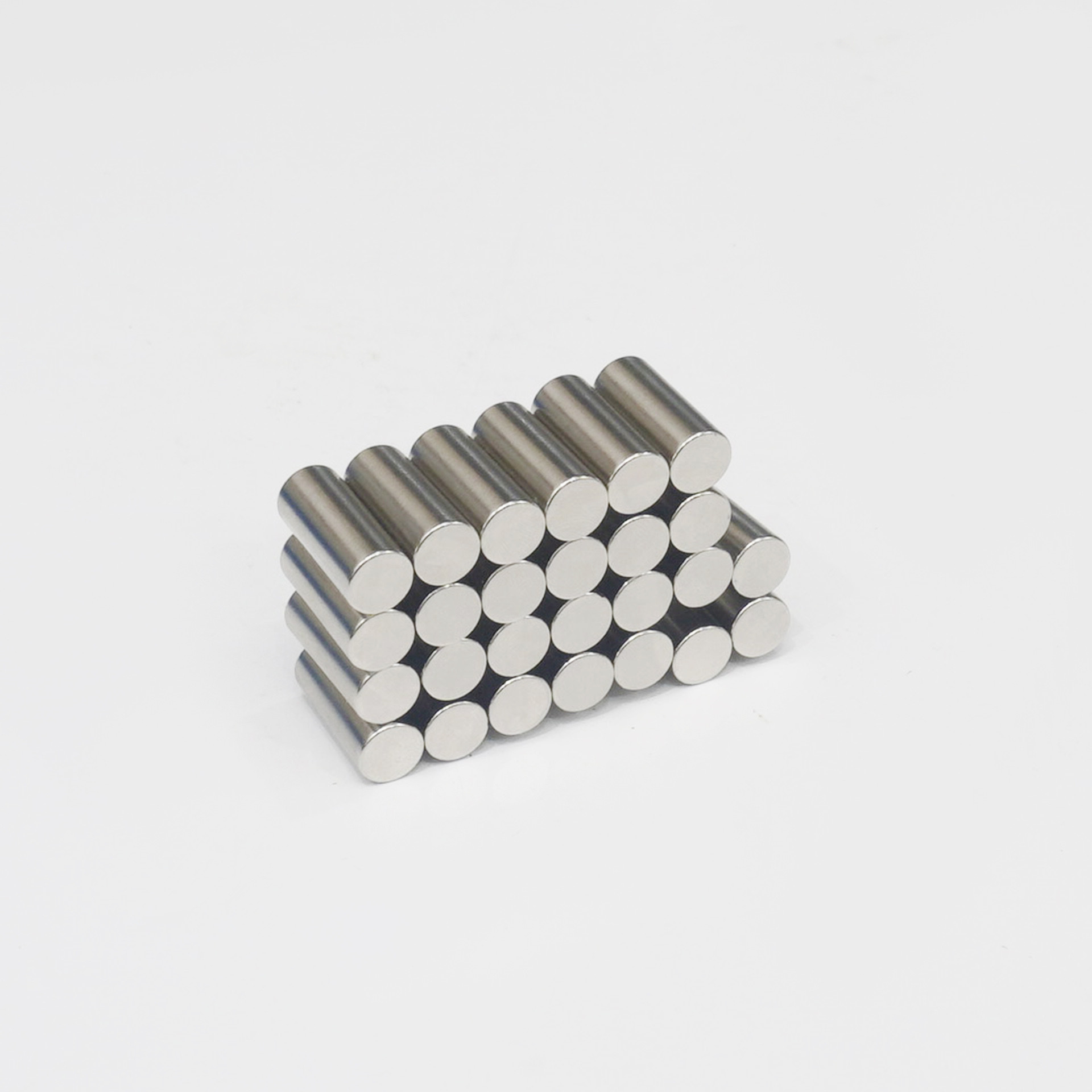

Platten Magnet Permanent Block

Application scenarios of Plates magnet:

1. Electronics industry

• Material: high-performance NdFeB (N52 grade).

• Coating: nickel plating or epoxy resin.

• Temperature requirement: below 100°C.

2. Medical equipment

• Material: anti-magnetic attenuation samarium cobalt (SmCo).

• Coating: Parylene or uncoated (high purity requirement).

• Special design: precise tolerance and low demagnetization rate.

3. Industrial motor

• Material: high temperature resistant AlNiCo or high-performance NdFeB.

• Temperature requirement: above 200°C.

Technical parameters of Plates magnet

Customized magnets need to consider the following important parameters:

1. Magnetic performance parameters

• Remanence (Br): The maximum magnetic field strength after the magnet is fully magnetized, in Gauss (Gs) or Tesla (T).

• Coercive force (Hc): The reverse magnetic field strength required to remove magnetism.

• Magnetic energy product (BHmax): The ability of a magnet to store energy, in MGOe or kJ/m³.

2. Dimensions and tolerances

• Length, width, height (such as 40×20×10 mm), the tolerance is usually ±0.05 mm to ±0.1 mm.

3. Temperature performance

• Operating temperature range: For example, NdFeB is generally 80°C~200°C, and AlNiCo can reach more than 500°C.

• Temperature coefficient: The stability of magnetic properties with temperature changes.

Plates magnet customization process:

1:Demand communication

• Customers provide application scenarios (such as electronic equipment, medical equipment, motors, etc.) and specify the use environment (such as temperature range, humidity, corrosiveness, etc.).

• Determine the shape (rectangular, square, special-shaped, etc.), size, magnetic requirements, coating, etc. of the magnet.

2:Material selection for plates magnet

• Select appropriate magnetic materials according to magnetic properties and use environment:

• Neodymium iron boron (NdFeB): high-strength magnetism, suitable for miniaturized equipment.

• Aluminum nickel cobalt (AlNiCo): excellent high temperature resistance.

• Ferrite: low cost, good corrosion resistance.

Design and confirmation

• Design engineering drawings, including magnet size, tolerance requirements and polarity distribution.

• Confirm whether other additional functions are required, such as drilling, chamfering and other processing.

1:Plates magnet manufacturing

• Sintering or bonding: materials such as NdFeB need to be sintered, while bonded magnets are manufactured using a bonding process.

• Processing: Processed into a specified shape using processes such as cutting, wire cutting or grinding.

• Coating: Add coatings (such as nickel plating, zinc, epoxy resin, etc.) according to customer requirements to enhance corrosion resistance.

Wir liefern zugelassene Neodym-Seltenerdmagnete in verschiedenen Formen, Größen, Premiumqualitäten (von N30 bis N52) und Oberflächenbehandlungen. Unser umfangreicher Bestand an NdFeB-Magneten umfasst Scheiben, Blöcke, Streifen, Ringe, Stäbe und mehr. Nicht alle unsere Magnete werden auf dieser Website angezeigt. Wenn Sie den benötigten Magneten nicht finden können, kontaktieren Sie uns noch heute und unsere Mitarbeiter sorgen dafür, dass Sie den besten Magneten für Ihre Anwendung finden.

Abonniere jetzt

Verpassen Sie keine zukünftigen Updates! Abonnieren Sie uns noch heute!

©2024. Dongguan Pegaint Magnet CO., LTD. Alle Rechte vorbehalten.