Nam châm vòng cung Neodymium hướng tâm: Sức mạnh đằng sau các rôto hiệu suất cao

Radial neodymium arc magnets are a critical component in modern high-efficiency motors and generators, especially in applications demanding compact design and maximum torque density. Engineered from NdFeB (neodymium-iron-boron), these magnets are shaped into precise arc segments and magnetized in a radial orientation—perfectly aligning with the circular geometry of rotors.

This configuration enables smoother magnetic flux distribution, minimizes cogging torque, and enhances motor efficiency. Commonly used in brushless DC motors (BLDC), electric vehicle drivetrains, wind turbines, and high-speed industrial equipment, radial arc magnets support the demanding performance requirements of today’s motion systems.

With high energy density, strong resistance to demagnetization, and customizable magnetization directions, radial neodymium arc magnets are driving the future of next-generation rotating machinery.

What Are Radial Neodymium Arc Magnets?

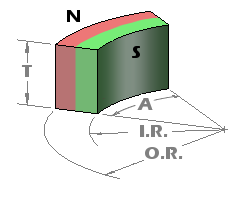

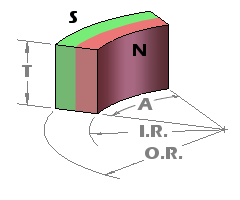

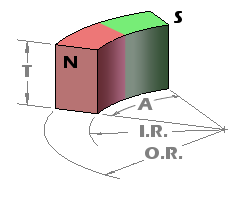

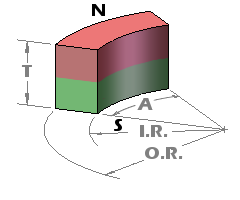

Radial neodymium arc magnets are specialized segments made from neodymium-iron-boron (NdFeB), the strongest type of rare-earth magnet available today. These magnets are shaped like arcs to fit around circular paths—typically the inner or outer circumference of electric motor rotors. What makes them “radial” is the direction of their magnetic field: instead of being magnetized through the thickness or length like standard arc magnets, they are magnetized from the center outward (radially), or vice versa.

Key Features:

• Shape: Curved/arc segments designed to form a ring when assembled.

• Magnetization: Radially oriented, allowing for smoother and more uniform magnetic fields in rotating systems.

• Material: Made from NdFeB, known for its high magnetic strength and energy product.

Các ứng dụng:

Radial neodymium arc magnets are commonly used in:

• High-performance electric motors (BLDC, servo motors)

• Wind turbine generators

• Automotive traction systems (EVs and hybrids)

• Aerospace actuators and robotics

These magnets are essential in designs where precision, compactness, and high torque density are required.

Would you like a visual diagram or cross-section to help illustrate how radial magnetization works?